Embossing Machine

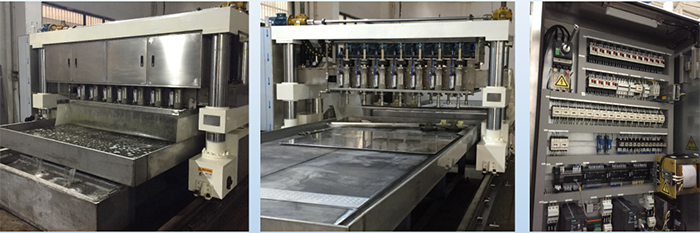

YH1600 Automatic Embossing/Stamping Machine

Description

This line is composed of 1600T 4-Column Press, Front and Rear Feeding Unit as well as Pressing Dies. It is suitable for High Tonnage Pressing of Antikaid Plate, Anti Slippery Plate, Safety Tread. The Machine is Specially Heat Treated and Bead Blasted, Thus, Inner Stress has been removed and Surface is Toughened, which can ensure the Precision of Long time working and maximally prolong the life span of both the machine itself and the Dies.

This machine is mainly used to make embossing sheets, anti-sliding plate. Frame is made of heavy duty welded steel, stress released. 1600 ton 4 column type Hydraulic Press will be controlled by Servo system. Dies Auto Move In-Out for easy replacement. Levelling function has been considered when design the die, which can guarantee the good flatness of the plate. PLC plus HMI is for easy operation and adjustment. Motor, reducer and hydraulic components will be applied.

Main Technical Parameters

| Construction | Close Type | Note | ||

| Nominal force | KN | 16000 | ||

| Max Sheet Thickness | mm | 6 | ||

| Max Sheet Size | mm | 1500X6000 | ||

| Feeding Precision | mm | ±0.2 | ||

| Repeating Positioning Precision of Origin | mm | ±0.2 | ||

| Max Stamping Frequency | Times/Min | 10 | ||

| Min Stamping Frequency | Times/Min | 6 | ||

| Working Hydraulic Pressure | MPa | 20 | ||

| Total Power | KW | 100 | ||

| Height of Pattern | mm | 1.2-1.3 | ||

| Workable Raw Material | Stainless Steel of 200/300/400 Series | |||

| Machine Weight | T | 40 | ||

| Machine Dimension | mm | 13500×3300×5300 | ||

Main Components List

| No. | Components | Make | Note |

| 1 | Feeder | HT | |

| 2 | 4-Column Press | Yangli | |

| 3 | Die | HT | |

| 4 | Pneumatic Components | Airtec | |

| 6 | Linear Track | Hiwin or ABBA | |

| 7 | Servo Motor Drive | Xinjie | |

| 8 | Screen | Weinview | |

| 9 | PLC | Siemens | |

| 9 | Electrical System | HT | |

| 10 | Module | Siemens | |

| 11 | Electrical Components | (1)Switch: Taiwan Mingwei (2)Proximity Switch, Relay: Omron |

|

| 12 | Three-Phase Asynchronous Motor | Famous Domestic Brand | |

| 13 | Bearing | NSK | |

| 14 | Hydraulic Components |

Supply Scope

| No | Products | Specs | Unit | Price | Q’ty | Note |

| 1 | Feeder | Set | 1 | |||

| 2 | Press | Set | 1 | |||

| 3 | Die | Set | 1 | As per Pattern | ||

| 4 | Spares | Set | 1 | |||

| 3 | Special Tools | No | ||||

| 4 | Installation and Commissioning | Free Installation and Commissioning | ||||

| 5 | Training | Free Training | ||||

| 6 | Manual | Disc | ||||

Machine Features

— Big Pressing Force, Workable in Large Scope

— Automatic Die Moving in and Moving out Function, very easy to change Dies. Many Different Patterns can be made as per requirement from Customers.

— Automatic Feeding System, Auto Position to Die Bottom, and Moves out after Stamping.

Man power is only needed to move sheets to Roller Table and Move out the Sheets after Stamping. Only One operator is needed.

— The die is with Leveling and Re-Shaping Function, Flatness of Sheets can be ensured after Stamping.

Buyer Scope

Air Supply: 0.6Mpa, 1 M3/Min, Dry and Clean Compressed Air

Power Supply: 415V, 50Hz, Voltage Fluctuation: -10%-+10%

Surrounding Temperature: 0°C – +40°C

Surrounding Humidity: Relative Humidity: 20-80%RH (Non Condensation)

Free from Strong Vibration Source and Electro-Magnetic Interference.

Free from Dust, Harmful and Etching Air

Foundation should be made as per Foundation Drawing from Supplier.

Straight and Flat S/S Sheets.

Stable and Educated Operator

Company Introduction

Our history:

Expert for Flat Surface Abrasives Belt Grinding of Metal: This target is guiding us keeping research in the metal grinding and polishing by coated abrasives field from 1990s.

In 2005 we started designing, manufacturing and assembling wide abrasives belt grinding machines for metal. With the continuous expansion of business and the changing of shareholder structure,

in 2015 WUXI Zhongshuo Precision Machinery Co., Ltd was founded.

Our Company:

We are an owner managed mid-size company. The company is located in Wuxi City, Jiangsu Province. The registered capital is 8 million RMB. The construction area exceeds 7000 m2. The total number of employees is 52, including 1 Research level engineer, 2 senior engineers and 5 engineers. We have a professional designing, manufacturing, assembly, installation, commissioning and sales service team.

Our Products

We produce wide belt grinding and polishing machine, brushing machine, mirror finishing machine, vibration finishing machine, embossing machine for metal coil and sheet, including entry and exit section of CGL (Coil to Coil Repairing Grinding Line for Steel Maker) and CPL (Coil to Coil Polishing Line for Service Center), i.e. Unwinder, Rewinder, Loading Car, Pinch Roll, Flattener, Crop Shear, Coolant Filtration and Recycling system, Washing and Drying system, Mist Collector, Fire Fighting system. We also provide Loading device with Vacuum Cups Group for Sheet to Sheet Grinding Lin

Our Clients:

Our reference list including Tisco Daming, Wuxi Puxin, Zhejiang Bohai and other well known Chinese customers. We exported our products to Europe country like Italy, Turkey with CE Certification. We also provide belt calibrating grinder to Chinese maker who is supplying the material to Aircraft and Nuclear In.

Our Certification

Projects

To create the value to the customer is our constant pursuit. Your satisfaction is the power of our continuous innovation.

CPL-Coil to Coil Polishing Line for Stainless Steel Service Center

CLIENT:浦新金属

CPL is applied mainly for the removal of small defects in cold rolling SS coil in wet, obtain the decorative finishing, i.e. No.3, No.4, HL, SB & Duplo. The coolant could be emulsion or mineral oil. Coolant filtration and recycling system is essential to the complete line. ZS CPL is designed for cold rolling coil to coil processing up from 100 to 1600 mm width and a thickness between 0.4 to 3.0 mm. WUXI ZS also provide CPL dry. Cork belt will be applied to obtain the finishing similar to Scotch-Brite finishing (SB), feeding speed of dry CPL could be 50m/min or more.

SPL-Sheet to Sheet Polishing Line(Wet Type)

CLIENT:太钢大明

Sheet to Sheet Grinding Machine (Wet Type) uses Grinding Oil or Emulsion as a Media to achieve a fine and shiny grinding effect on either hot or cold rolled stainless steel sheets or coils. The Machine is designed to get Finishing No.3 (Coarse Finishing, Abrasive Grain From G60 to G150 ) or No.4 (Fine Finishing, Most Popular, abrasive grain from G180 Or above) and HL Finishing (Hairline Finishing, Characterized by Smooth and long line ). ZS SPL is designed for cold sheet to sheet grinding processing up from 600 to 2200 mm width and a thickness between 0.4 to 3.0 mm.

PGL-Grinding Polishing Line for Heavy Plate

CLIENT:西部金属

Full Automatic Grinding and Polishing Line is applied mainly for the removal of defects from hot rolling, pickling & annealing process and residual scale, and achieve the requested thickness and roughness. The coolant could be emulsion or mineral oil. Coolant filtration and recycling system is essential to the complete line. ZS PGL is designed for processing of hot rolling heavy plate from 600 to 2200 mm width and a thickness between 1.0 to 30 mm. WUXI ZS also provide PGL dry.

Mirror Finishing(8K) Machine for Stainless Steel Plate

CLIENT:新华医疗

Advantage of WUXI 25 Mirror Finishing Machine for Stainless Steel Coil and Sheet . Polishing heads of each group can be independently or integrally lifted up and down . Center refiling of polishing compound to avoid surface underneath the polishing disc get burnt. Stainless steel made . Anti corrosion and long life. Smooth reciprocating movement by linear guide.

Mirror Finishing Machine for Cold Rolling Coil and Sheet

CLIENT:MINOX(INDIA)

Pinch roll type. It applies resin bonded grinding wheel, Scotch-Brite disc, polishing compound comprising of 5% Al2O3 + 5% nitric acid + 90% water to improve the surface roughness step by step, finally super mirror finishing can be obtained (8K).

Automatic Loading/Unloading Device with Vacuum Cup Group

CLIENT: 博海金属

It consists of a gantry frame made of welded, carbon steel and suitably dimension to support the working stress. The device consists of the following groups: Translation unit, Lifting unit, Vacuum pick up unit.

The translation unit is guided by the liner guide, driven by the servo motor via gear and pinion. The lifting unit guided by the liner guide, driven by the pneumatic piston. The pick-up unit is composed of 3 adjustable holder bars with 18 suction cups, the bar is in a fixed position but each suction cup can move longitudinally, the operator can release the fixture, adjust the position of the suction cup, lock again the fixture easily.

Each suction cup is connected to the individual pneumatic piping to ensure the smooth operation of the system, each suction cup is connected to the spring arbor to ensure the enough buffering space between cups and work piece.

Automatic Laminator for Film Protection (PVC Coating Machine)

CLIENT: STEEL COLOR(ITALY)

Automatic Laminator / PVC Coating Machine is used mainly for the Film Lamination on Sheet Surface. It can be designed for Double side Double layer Laminating.

Automatic Lamination, Automatic Cutting.

* Machine Mode: 400-2500 Type

* Workable Width: 400-2500MM

* Working Speed: Fixed Speed/Adjustable Speed

* Application: This machine is mainly used in Coiler/De-coiler System,

Polishing Machine, 8K Mirror Polishing Machine, Cut to Length Line,

Grinding Machine Etc.

* Machines can be tailor-made.